Wiring up electrical systems gives me the ‘heebie jeebies’ – I’m never very sure whether the sneaky little electrons will go where I want them to go or if the wires will suffer a melt-down (thereby letting ‘the smoke get out’ of them).

Wiring up electrical systems gives me the ‘heebie jeebies’ – I’m never very sure whether the sneaky little electrons will go where I want them to go or if the wires will suffer a melt-down (thereby letting ‘the smoke get out’ of them).

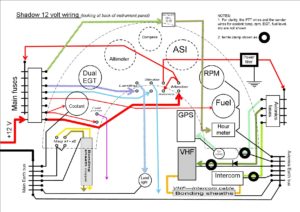

I’d already spent hours on the computer working on wiring diagrams – colour-coded wires, switch banks, earth buses, filtered avionic supply, etc. That’s all very nice, but eventually someone has to cut

actual wires and crimp on actual connectors. I’ve sat at the nose of the Shadow for quite a few hours tentatively cutting, labelling and crimping. After the first session, I’d done five wires, and only made two mistakes! One was too short. Another had the wrong label.

The final result is OK I think, but needs a better way to support the bundle of wires.

The final result is OK I think, but needs a better way to support the bundle of wires.